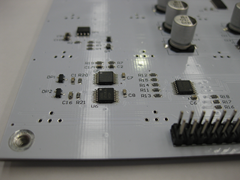

I received my boards back from the manufacturer last week, and I've fully populated a few with components for software testing. So far everything has gone without a problem, aside from a few niggling software problems that have since been rectified.

I’ll make another update once I've got a small array of these boards connected and running, but for now here are some pretty pictures (note that I decided to change the silkscreen and solder-mask colours to black and white respectively, but otherwise the design is unchanged from previous blog updates).

|  |  |

| Fig.1: The ICs | Fig.2: The Full Board (Back) | Fig.3: The Logo! |

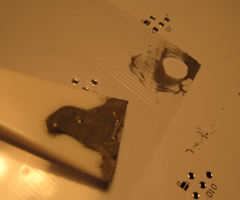

When I showed a colleague the board today, he asked if I had had a problem with solder getting into the thread of the surface-mount mounting nuts, but when I said that they were hand-soldered, he told me that it was probably only an issue for the reflow-soldered process. Because of this, I decided to run a quick test. I made a crude stencil using an overhead-transparency sheet, applied solder to the mounting hole - screen-printing style – and then use my IR soldering station to reflow the solder.

From the images below, the only problem I could see was that perhaps I had applied too little solder since there appears to be a gap when viewing the nut from below. However, no solder entered the nut and blocked the thread on any of the four attempts.

|  |

| Fig.4: Stencil and Spatula | Fig.5: Pasted |

|  |

| Fig.6: Inserted | Fig.7: Reflowing under IR |

|  |

| Fig.9: Reflowed Version | Fig.10: Hand Soldered Version |

No comments:

Post a Comment