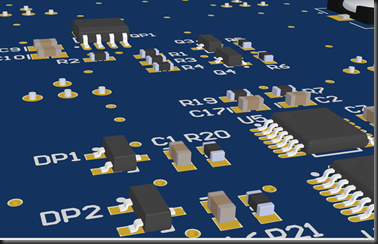

I've been messing around with embedded software for the last few weeks, but lately my time's been dominated by linking some proper 3D models to my PCA for accurate component clearance checking.

The key areas I was unsure about with my current design were:

- Through-hole LEDs

- Through-hole connectors

- Surface-mount capacitors

- Surface-mount fasteners

The LED-to-fastener conflict had a chance to be a game-changer, so I decided to 'do things right' by using the tools available to me; a combination of Altium and SolidWorks.

A lot of the models I used were readily available for free on various manufacturer websites and forums, which made short work of a lot of it. Some that I've used are:

- Texas Instruments - Their data appears very accurate, although a couple of their web-links are broken and I've asked for them to be fixed.

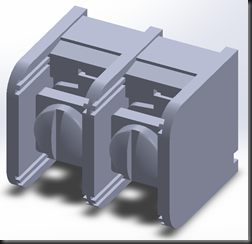

- TE Connectivity - Excellent 3D models for connectors, but without colour in the one I used.

- PEM Fasteners - Again, great models, but with some colour 'issues'.

- http://www.3dcontentcentral.com - The Dassault Systèmes (makers of SolidWorks) website for anyone to upload free components.

I downloaded all my passive 'chip' components (resistors, capacitors, inductors) from 3D Content Central, and a couple of ICs too, but most of the ICs I got from Texas Instruments, although as I said, one of their links for the HTSSOP28 chip was broken, so I've substituted a TSSOP28 (no thermal pad... not that it matters from a purely visual point of view) for the TLC5940s (I can't remember if I noted previously that I've switched from the through-hole to one of the surface-mount variants for reasons of cost).

The model for the PEM Fasteners SMD threaded-nut I've purchased came with an orange colour on the threading which may be to highlight that a) the threading wasn't modelled, or b) that it is a contact surface, but I didn't want it to look unrealistic, so I changed it to silver. The Tyco barrier-terminal model came without any colour information, which I suspected may have been due to them using an older .STEP file format, but it appears to be a STEP AP214 format which should have colour options. This became a simple matter of using SolidWorks to import the file, add the colour to the appropriate surfaces, and save as an updated .STEP model, as shown below in the before and after images:

|  |

| Figure 1: Connector before adding colour | Figure 2: Connector with colour |

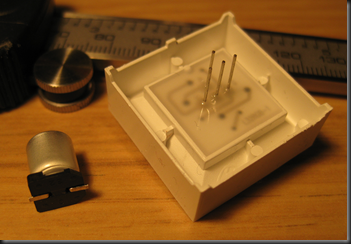

The first component I had to make from scratch was the tri-colour LED that is placed in an array across the entire top-side of the board. I didn't have great technical documentation for the 'internals' of the component, so my digital callipers came in handy. Previously I had modelled the component as a single flat-block, but this caused clashes with one bottom-layer component (the Tyco barrier-connector) and one top-layer component (the SMD fastener). While I knew I could probably get away with an educated-guess as a valid position where the components wouldn't collide, it's always better to be sure.

|  |  |

| Figure 3: LED Front/Side/Bottom/Top | Figure 4: LED Iso Above | Figure 5: LED Iso Below |

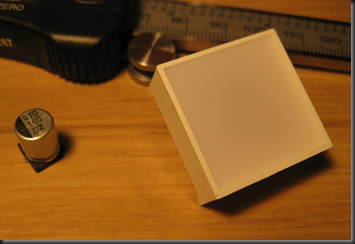

The second component was the KEMET EDK-Series SMD 16V, 470uF electrolytic capacitor. This provided some more good design 'revision' with SolidWorks (which I haven't touched in over a year). It was a relatively simple component to model, and I found that when I needed to revise one of the dimensions I'd set early on, the method I'd used to link my 'Smart Dimensions' - as they're called - meant that the model was automatically realigned and adjusted for the change. Handy!

|  |  |

| Figure 6: Kemet from all angles | Figure 7: Kemet Iso Above | Figure 8: Kemet Iso Below |

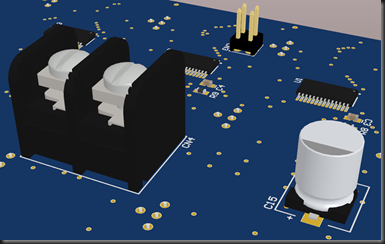

And here are those two components in real life in their natural environment:

|  |

| Figure 9: Capacitor right, LED Left | Figure 10: Capacitor right, LED Left |

So with all the components modelled, I was able change the layout from this:

|  |

| Figure 11: Leadless-components | Figure 12: Missing Connectors |

...to this:

|  |

| Figure 13: Front | Figure 14: Back |

|  |

| Figure 15: ICs and colourful 'jellybeans' | Figure 16: Barrier Terminal, header pins, capacitor |

Now that all the components are spatially accurate, I can see that there is no longer a problem with clashes between components:

|  |

| Figure 17: Fastener has tight fit | Figure 18: Spacious fastener |

One thing to note is that I have the footprint for the electrolytic capacitor slightly larger than necessary so that I can temporarily use a few larger 35V 470uF capacitors that I acquired cheaply.

Hopefully I'll get the board off to the manufacturer tomorrow. It's always best to sleep on a design and re-check for design faults in the morning; a 'cooling-off period'. :)

Hi,

ReplyDeleteyou have a really nice site and the STM32F4 sample code was really helpfull. I now have seen those nice square RGB LEDs, could you tell me where you get them from?

Best regards,

Phil

The LEDs are from a Taiwanese LED manufacturer called "Royal Light Electronics" which I discovered while working for a previous employer.

ReplyDeleteI had difficulty communicating with them, but had a friend and colleague help me with the translations.

They also didn't want to provide samples, so I had to purchase the MOQ.

Thanks a lot for your answer.

ReplyDelete